Imagine you’re in a senior role at a major utility company, charged (no pun intended) with executing a billion-dollar investment plan. On the morning a big construction project is set to kick off, with a large crew and an armada of assets already deployed, you receive a call. You can’t have the planned outage needed to complete the day’s work.

For John Parks, this exact scenario was a regular source of frustration at Pacific Gas & Electric Company (PG&E). “Every year we struggled to obtain the outage windows we needed to get our work done,” he said. In his current role with Smart Wires, Inc., Parks gets to be part of the solution.

Smart Wires: Reimagining the Grid

Smart Wires has developed technology that’s able to dynamically change the reactance of high voltage electric lines. SmartValve™ can push power off of overloaded lines or pull power on to under-utilized pathways, solving problems on the grid by taking advantage of excess capacity that exists on the system.

“I knew Smart Wires from my time at PG&E,” Parks said. “We installed a fixed deployment of their technology and were very pleased with its performance.”

In order to leverage Smart Valve technology for short-term challenges, such as securing outages for construction or maintenance, utilities needed to be able to install the device within a few hours. Although Smart Wires products are inherently designed to be installed quickly and easy to redeploy, the market was asking for a truly mobile solution. Enter Nomad.

Nomad GCS: Forging a Mobile Future

“Nomad demonstrated a unique ability to think outside the box with a proven track record of delivering complex, custom vehicles for critical needs,” said Smart Wires’ Director of Mobile Solutions, Casey Heier. “Their willingness to tackle difficult problems and quickly respond to our requests made them an ideal partner.”

We kicked off the partnership with an extensive engineering study, which shaved hundreds of production hours off earlier estimates. CEO Will Schmautz credits Nomad’s agile, vertically-integrated processes with enabling those kinds of efficiencies. “Smart Wires had some unique requirements for this project that demanded ingenuity, plus the expertise to rapidly design, prototype, and iterate. That combination is right in our wheelhouse,” he said.

We want to deeply understand who we’re serving, how we can make their world better, and then work together toward a creative solution.

Of course, all the experience in the world means little if you lose sight of the customer. Throughout the build, both Nomad and Smart Wires maintained a laser-focus on the end user. “Our customers really drove the creation of the mobile solution,” Heier noted. “Their insights were critical in developing the product requirements.”

Schmautz agrees. “Neither of our companies is interested in building ‘ordinary’ products. We want to deeply understand who we’re serving, how we can make their world better, and then work together toward a creative solution.”

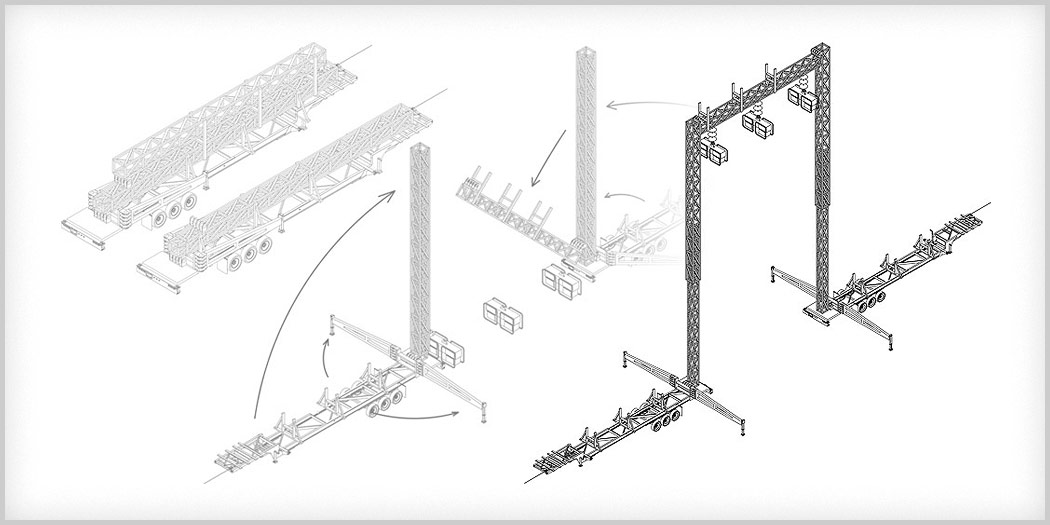

Over several months, the teams collaborated with the rare mix of imagination, flexibility, and attention to detail that leads to breakthroughs. Concepts showed wide-ranging approaches, including an early design that would have Smart Wires devices deployed from above power lines, anchored by two opposing trailers.

Design, Iterate, Repeat

Nomad Engineer Bryce Puchta said about the evolving design, “Many aspects of this project were slimmed down and simplified. Reducing the number of components, refining setup and tear-down processes, improving repeatability… All of these design choices led to a great result.”

Naturally, any boundary-pushing venture is going to encounter challenges and pitfalls. Will Schmautz elaborates, “Rapid iteration can have the unfortunate side effect of scope creep. We fought against this by continually coming back to the needs of end users, checking plans against the aspirations that originally drove the project.” When requirements do change, communication is key. “Having an open line with Smart Wires let us have ongoing conversations, negotiations, and points of agreement,” Schmautz said.

Across the Finish Line

The end product delivers Smart Wires’ solution inside a highly-modified intermodal (ISO) container, with all components completely integrated. Hydraulic lifts inside are synchronized to raise and lower the six power flow control devices at identical rates.

The mobile power flow solution can be commissioned quickly and deployed easily with minimal resources, helping utilities get critical reconductoring, construction, and maintenance projects done on time and on budget.

It is the kind of inevitable outcome that makes you say, “Of course they did it this way.”

Could innovative design thinking energize your utility operations?

Learn more about our approach here. Then…